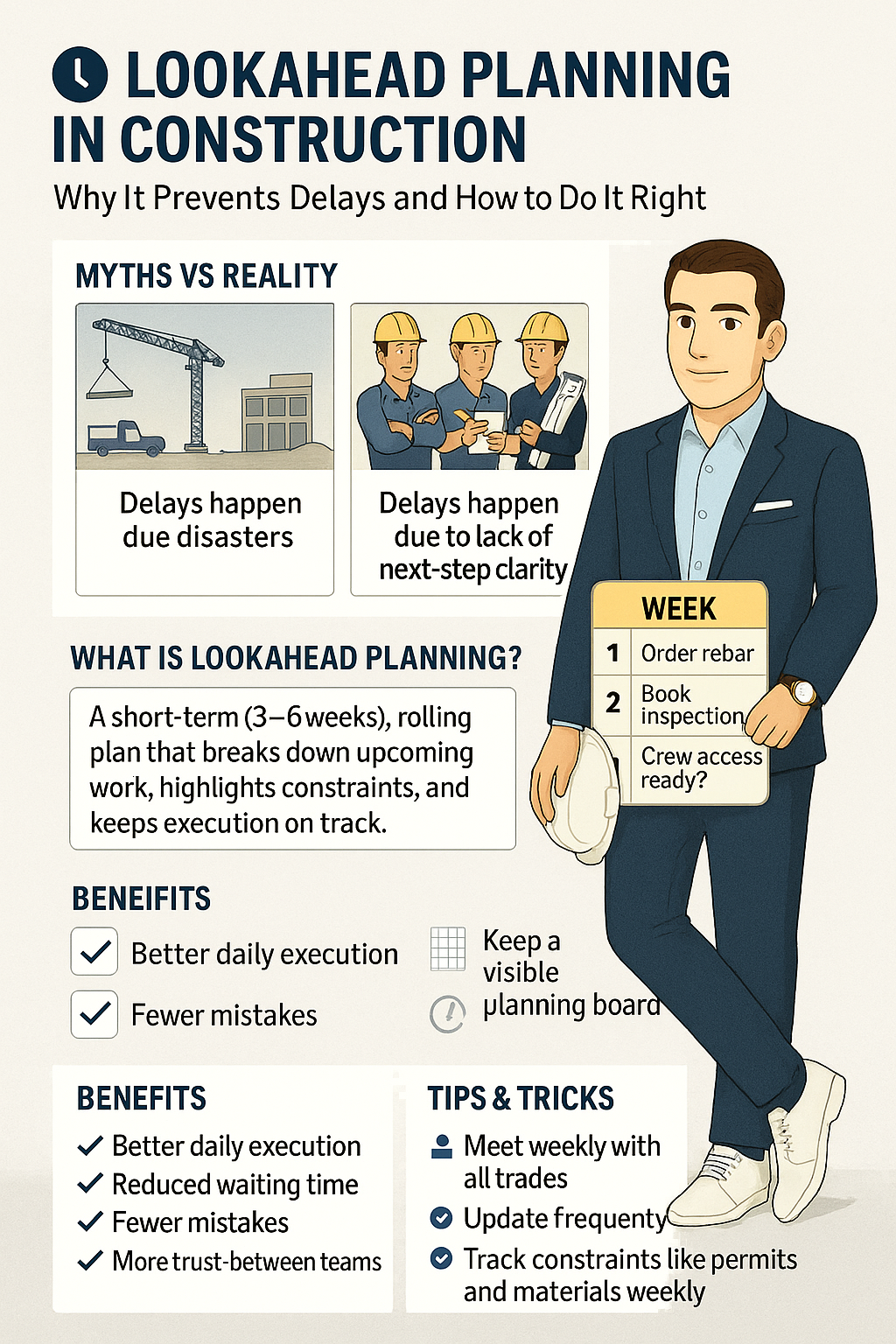

Many people think that big problems cause big delays. That is not always true. Most delays do not begin with something dramatic. They usually start with small, quiet issues. These can be missed checks, idle teams, or unclear next steps. Without attention, these small issues grow. Each one adds to the delay. It becomes hard to notice the real cause. Over time, the project slows down. This is how drift begins, and it often happens when there is no proper lookahead planning.

WHAT IS LOOKAHEAD PLANNING?

Lookahead planning is a short-term planning method used to organize upcoming construction activities. It typically covers a period of two to six weeks. The goal is to break down larger tasks into clear steps. These steps must be assigned to specific teams and tracked for progress. Lookahead plans help to identify what might go wrong before it happens. This includes materials not arriving, approvals not being ready, or access problems. When these risks are seen early, they can be managed more effectively. Without a lookahead plan, site teams may wait for direction. This leads to lost time and increased costs.

WHY LONG-TERM SCHEDULES ARE NOT ENOUGH

Master schedules show the full project timeline. They are useful for high-level planning. However, they do not give clear direction for daily site work. Teams on site need detailed instructions. They need to know what is happening tomorrow, next week, and the week after. If they only follow the master schedule, important details can be missed. For example, a task may be listed, but the required materials may not have arrived yet. Or an inspection may not be booked in time. These are the types of issues that cause unexpected delays. A lookahead plan helps to fill this gap between high-level plans and daily execution.

KEY ELEMENTS OF AN EFFECTIVE LOOKAHEAD PLAN

A strong lookahead plan should be detailed, realistic, and regularly updated. It must include the following elements:

- Specific tasks for each trade

- Clear timeframes for each activity

- Materials needed for upcoming work

- Approvals, inspections, or permits required

- Access to the work area and safety considerations

- Coordination between trades to avoid conflicts

- Buffer time for unforeseen events

These elements help ensure that everyone is prepared and knows what to expect.

BENEFITS OF LOOKAHEAD PLANNING

Lookahead planning improves communication between all project members. It allows teams to prepare in advance. It reduces waiting time. It also prevents unnecessary changes in the schedule. When tasks are clearly defined and shared, confusion is minimized. It is easier to manage work zones, deliveries, and inspections. Lookahead planning also supports better use of equipment and labor. This improves productivity and reduces idle time. Over time, these small improvements lead to better overall project performance.

RISKS OF NOT USING LOOKAHEAD PLANNING

Without a lookahead plan, teams may be unsure about what to do next. This uncertainty can lead to:

- Teams waiting for decisions

- Delays in material delivery

- Missed inspections or approvals

- Overlapping work and safety risks

- Last-minute changes to the plan

These issues often lead to rework, extra costs, and frustration. In larger projects, the effect can multiply quickly. A small delay in one area can affect many other tasks. This is known as delay stacking, and it becomes harder to manage the longer it continues.

HOW TO CREATE A LOOKAHEAD PLAN

To create a useful lookahead plan, follow these steps:

- Review the master schedule

- Break down tasks for the next 3 to 6 weeks

- Meet with each trade to confirm their plans

- Identify all resources and constraints

- Assign responsibilities and due dates

- Share the plan with all team members

- Update the plan every week based on progress

This process keeps the plan accurate and useful. It allows the team to adjust early if needed.

TOOLS FOR LOOKAHEAD PLANNING

There are many tools that can support lookahead planning. These include spreadsheets, scheduling software, and planning boards. The important part is not which tool is used, but how it is used. A simple spreadsheet can be effective if it is updated regularly. Software tools can offer automation, visual timelines, and notifications. Choose the tool that works best for your team. Focus on clarity, access, and ease of use.

COMMON MISTAKES TO AVOID

Some common mistakes in lookahead planning are:

- Not involving the site team

- Making the plan too complex

- Forgetting to include inspections or approvals

- Ignoring supply chain timelines

- Skipping regular updates

These mistakes reduce the value of the plan. Keep the plan simple, clear, and useful. Review it weekly with the people doing the work.

CONCLUSION

Lookahead planning is a simple but powerful method for reducing delays in construction projects. It brings clarity to daily activities and helps teams work with confidence. When used properly, it supports better coordination, improves productivity, and protects the project schedule. Every site can benefit from this approach, regardless of project size or complexity.

Tips and Tricks

FOR EFFECTIVE LOOKAHEAD PLANNING

✅ Use a weekly planning meeting to review progress and adjust the plan

✅ Include trade partners early to catch coordination issues

✅ Keep the plan visible in the site office or shared drive

✅ Track procurement and approvals in the same document

✅ Use color codes to highlight risks and critical activities

✅ Assign a single person to manage and update the plan

✅ Keep buffer time in high-risk areas

✅ Compare the lookahead with actual progress each week

✅ Train team members on how to use and read the plan

✅ Focus on communication — the plan should answer “what’s next?” clearly