The crew was quiet, but the tension was loud. James walked the muddy jobsite, watching his foreman improvise around yet another schedule slip. The steel delivery was late. Again. The concrete pour scheduled for today? Postponed. No one yelled, but no one smiled either. Somewhere between kickoff and now, the project had started drifting, and no one could point to exactly when it happened. One in three construction projects run over schedule due to miscommunication or scope issues, according to a 2023 report by McKinsey. Yet the signs are rarely dramatic. It’s not one big mistake. It’s many small ones, silently stacking up. Just like James’s project.

What you’re about to read isn’t just another blog post. It’s a story — one that mirrors countless real-life jobsites across North America. We’ll walk through James’s journey, not as a warning, but as a lesson: how easily missteps at the start of a construction project can spiral into costly chaos. Then, we’ll unpack what actually went wrong, and how it could have been prevented using modern methods and tools.

The First Story: James’s Chaotic Project

James was a seasoned project manager with a solid reputation. His new mid-rise commercial build was supposed to be a model job — clean paperwork, experienced crews, and a comfortable buffer in the timeline. But things started going off-track just a few weeks in.

It began with the scope. The architect sent final drawings late. The client requested small changes — a few more windows, a lobby redesign, nothing major. James, under pressure to start, greenlit excavation without locking the scope. His assumption? Details would settle while work progressed. But each week brought a new change. Design tweaks triggered pricing debates, field confusion, and permit delays. James tried to manage it all on calls and scattered emails.

Then came the schedule. In a rush to meet the client’s aggressive deadline, James built the master schedule himself — without input from site leads. It looked good on paper but didn’t reflect actual field conditions. One trade delayed the next. Crews overlapped in tight zones. Productivity dropped. Field leaders felt ignored and began freelancing their own workflows.

As weeks passed, scope changes snowballed. Mid-project, the client requested energy-efficient upgrades. James approved them verbally to keep momentum. There was no formal change order. The budget ballooned, the schedule cracked, and field crews became unsure what version of the plan they were building.

Worst of all, field progress tracking was sloppy. Supervisors gave vague updates. No one was logging percent complete daily. James had no clear picture of where the job really stood. So he kept reporting optimism up the chain — right up until the project hit a wall.

Let’s break down where James went wrong and how to fix it.

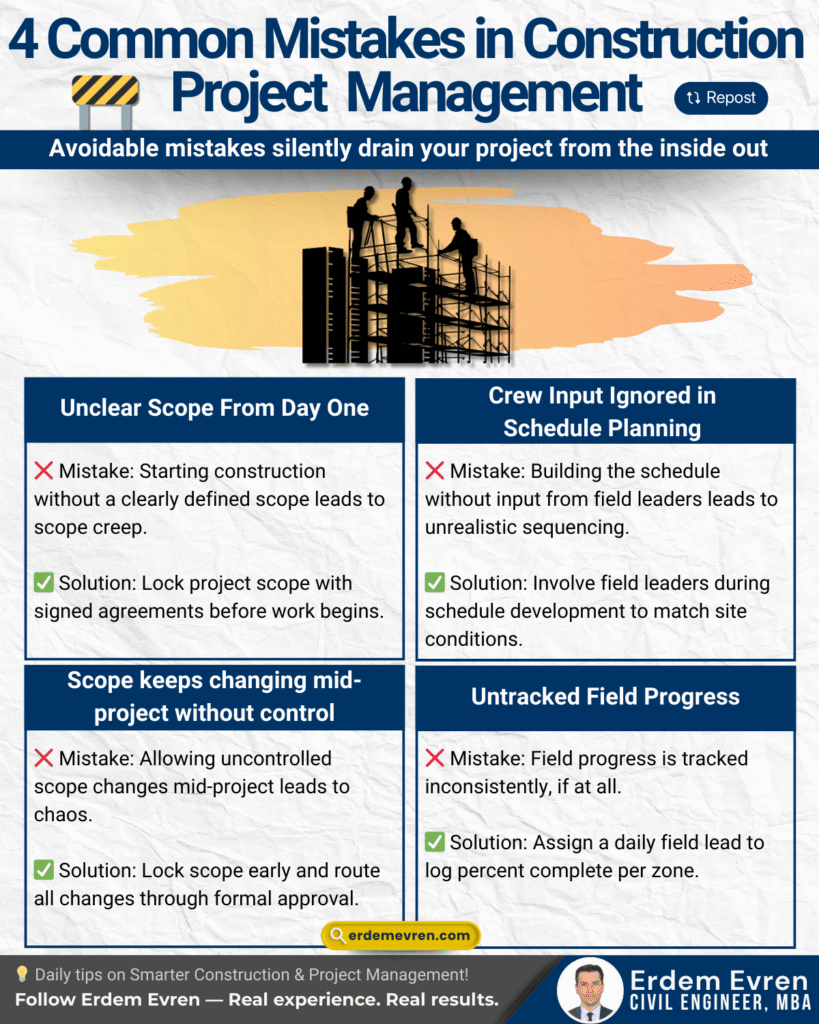

Unclear Scope from Day One

Problem: James started construction before locking down the full scope.

Impact: This led to cascading changes that affected budget, sequencing, and stakeholder trust. It created a moving target that the entire team struggled to hit.

Fix: Use modern platforms like Procore or Buildertrend to manage scope documents with digital sign-offs. Lock scope through formal agreements. Communicate clearly that no work begins without client signoff. Build a 2-week buffer before mobilization for scope clarity.

Crew Input Ignored in Schedule Planning

Problem: James built the schedule without input from the field team.

Impact: The schedule didn’t reflect site realities. Trades clashed, and sequencing fell apart. Morale dropped, and rework increased.

Fix: Adopt tools like Touchplan for collaborative scheduling. Bring site foremen and crew leads into planning sessions. Walk the site together. Build the schedule from the ground up — not the office down.

Mid-Project Scope Changes Without Control

Problem: James allowed verbal approvals for changes without documentation.

Impact: The budget was undermined. Crews built to outdated plans. Change orders stacked up post-facto, causing payment disputes and audit headaches.

Fix: Use approval workflows in Procore or Monday.com to route every scope change through a documented, signed process. Set strict rules: no drawings, no change.

Untracked Field Progress

Problem: Daily progress was not logged or quantified.

Impact: Leadership had no real-time data. Resource planning became reactive. Reporting was inaccurate. Problems emerged too late to course correct.

Fix: Assign a dedicated field lead to log percent complete each day using tools like Raken. Visual dashboards help PMs see slippage early. Set daily 4PM reporting deadlines for accountability.

The Second Story: Lisa’s Well-Run Project

Lisa was managing a similar project across town — a five-story medical office build with strict quality standards and a tight occupancy deadline. From the outset, she approached every step with discipline.

She held a two-week preconstruction freeze. No work would begin without a signed, final scope. All changes, even minor ones, were routed through Procore with timestamps, approvals, and document updates. Everyone had access to the current version.

For the schedule, Lisa invited all trade foremen and key suppliers to a collaborative planning session using Touchplan. They walked the site together, identified overlaps, and created a realistic sequence. The result? No crew stacking, no wasted days.

She also assigned a field coordinator whose only job was to log daily progress. Using Raken, they tracked completion rates by area, highlighted red flags, and synced updates to Lisa’s dashboard. She reviewed them each night and adjusted resources by morning.

When the client requested HVAC changes mid-project, Lisa didn’t blink. She logged the request, ran a quick cost and time impact analysis, and routed the change for digital signoff. No confusion. No assumptions. Just process.

Because everything was structured, Lisa’s team delivered two weeks early. Costs held within 1.2% of the original budget. The client praised the clarity. And the crew? They asked to be assigned to her next job.

Before vs After

Before James corrected course, the project had no clear scope, no collaborative schedule, and no consistent field tracking. Stress levels rose. Trust fell. The client was frustrated, and the crew was demoralized.

After implementing structured scope controls, involving the field team in planning, and adopting real-time tracking tools, progress improved visibly. Change requests were documented. Weekly reports became accurate. Crews aligned. The project didn’t finish ahead of schedule, but it finished under control — and that saved reputation and budget.

In contrast, Lisa never faced chaos. She built structure from day one. Because of that, there were no fires to put out. Only steady progress, predictable costs, and high team morale.

Why Most Fixes Cost Less Than the Mistakes

James learned the hard way that rushing into work without clarity costs more than delaying kickoff to plan better. Digital tools, field input, and real-time visibility aren’t luxuries — they’re the new baseline. Most construction failures don’t come from big blowouts. They come from the silence: missed details, unchecked assumptions, and soft habits.

The good news? These issues are fixable. They just require the discipline to slow down at the start and the systems to stay sharp as you go.

If you’re serious about improving outcomes, start with clarity. Grab our free mistake prevention checklist and walk your site this week with new eyes.

Summary

Construction project mistakes rarely explode — they leak. A missed signature, a skipped meeting, a half-tracked milestone. But when you build clarity from day one, involve the right voices, and keep tracking in real-time, the chaos stays contained.

Tips & Tricks to Keep Your Project on Track

• Lock your scope with signed client approval before the first shovel hits the ground.

• Invite field leaders to co-author the schedule. Their insights will save you weeks.

• Use one tool (not ten) to manage change requests, RFIs, and documentation.

• Set a 24-hour rule: no verbal approvals are considered valid unless logged and signed.

• Walk the jobsite every morning with your foreman to spot scope drift early.

• Don’t wait for weekly meetings — review daily progress reports every afternoon.

Construction Mistake Prevention Checklist

☑ Scope is fully defined, signed, and distributed before construction starts.

☑ Field leaders are consulted during schedule development.

☑ All scope changes require formal written approval.

☑ Daily progress is logged by a designated lead using digital tools.

☑ Visual dashboards track key metrics (percent complete, delays, change requests).

☑ Project documents are centralized and version-controlled.

☑ All verbal decisions are followed up with written confirmation.

☑ Field walk-throughs occur regularly with the PM and superintendent.

🚧 Need expert help? → Book a 1:1 consultation for your construction project management, planning, or automation challenges.

📚 Looking for powerful industry reads? → Visit my recommended books page for construction, leadership, and tech picks.

👷 Want gear and tool suggestions? → See my recommended gear list.

📬 Join the inner circle → Subscribe to the newsletter and get actionable project tips every week.

🌍 Explore my global experience → View projects I’ve contributed across 7 countries, including mega-developments and complex infrastructure work.

🔗 Stay connected → Follow me on LinkedIn for daily insights, behind-the-scenes breakdowns, and expert construction management content.